Rivium 2e straat 22 BG A1 2909LG Capelle aan den IJssel Netherlands | Phone: +31 6 4268 4131

Support

+31 6 4268 4131

A coupling is a mechanical component used to connect two rotating shafts at their ends in order to transmit torque from one shaft to the other. Beyond simple connection, couplings play a crucial role in compensating for misalignment, protecting equipment from overload, and minimizing vibration and wear.

While most couplings maintain a constant connection during operation, some—such as torque-limiting couplings—are designed to slip or disengage when a pre-set torque limit is exceeded. This feature is especially important in preventing damage to machinery under sudden load increases or malfunctions.

Properly selected and maintained couplings can have a significant impact on system performance, reliability, and cost efficiency. They help reduce wear and tear on connected components, limit downtime, and can absorb shock and vibration—extending the life of your equipment.

Couplings come in various designs, each suited for different operational demands. Banomad B.V. classifies couplings into three main categories:

Rigid couplings are used in applications where exact shaft alignment is required. These couplings provide a solid connection but offer no flexibility. Any misalignment can lead to increased stress on equipment and reduce the lifespan of both the coupling and connected components.

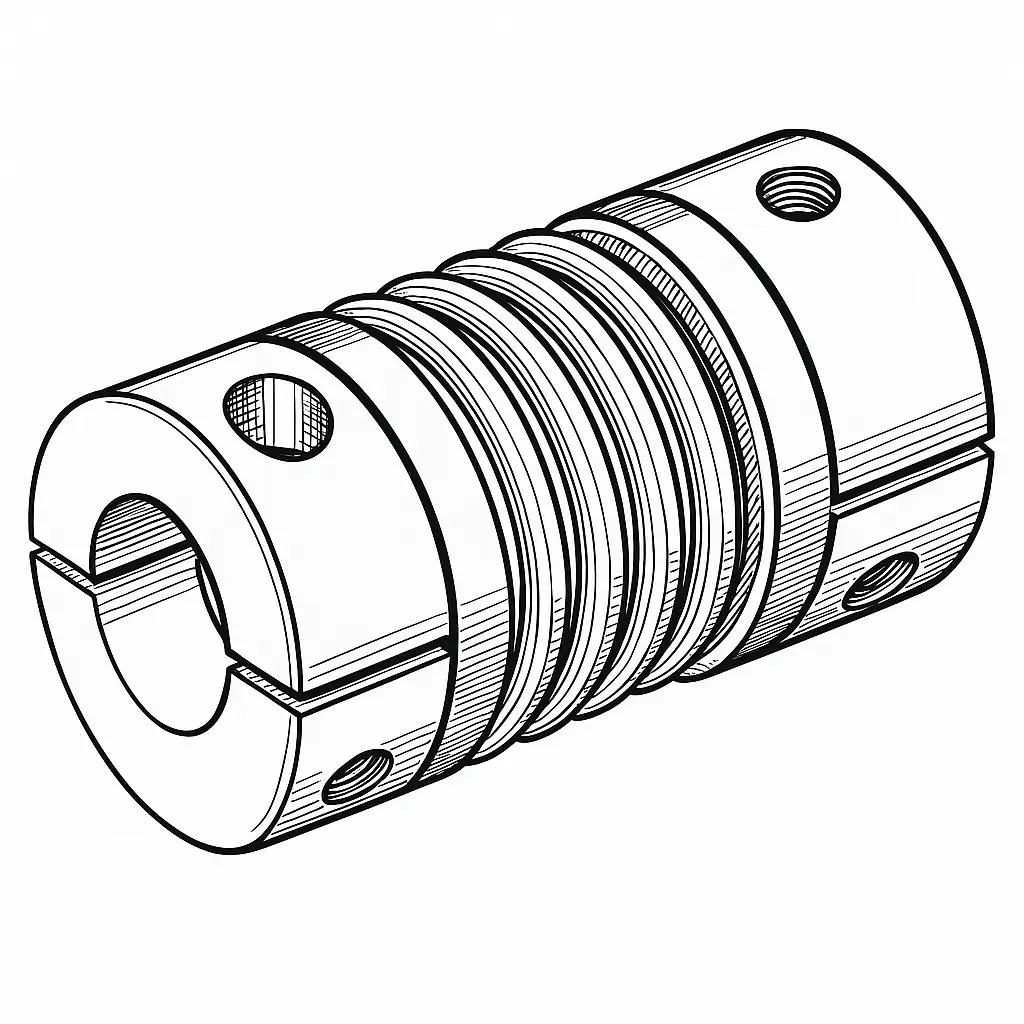

Flexible couplings are engineered to accommodate radial, axial, and angular misalignments. They help reduce vibration, compensate for shaft positioning errors, and protect system components. This makes them ideal for systems with slight but unavoidable shaft deviations.

These couplings protect systems by disconnecting or slipping when torque exceeds a defined threshold. They are essential in applications where overload protection is critical to avoid system failure or damage.

At Banomad BV, we offer a wide range of high-quality couplings designed for both marine and industrial applications. Whether you’re looking for a flexible connection or need to safeguard your system against overload, we can deliver the right solution.

Our product range includes:

Elastomer Couplings – Excellent vibration damping and compensation for misalignment.

Curved-Tooth Gear Couplings – High torque capacity and compact design.

Torsionally Flexible Couplings – Ideal for applications requiring flexibility and vibration damping.

Curved-Jaw Couplings – Easy to install and maintain, with moderate flexibility.

Rigid Couplings – For precision alignment and high torque transmission.

To ensure minimal downtime, Banomad BV maintains a comprehensive stock of the most commonly used coupling types and sizes. Thanks to our reliable supply chain and strong relationships with leading manufacturers, we can offer fast and dependable delivery to meet your operational timelines.

Because we are not tied to any single manufacturer, Banomad BV is able to offer objective advice and tailor our solutions to your specific technical and commercial requirements. Our experienced team works closely with customers to identify the optimal coupling for every application.